Carbon fibre may seem like a cutting-edge material created for modern cycling performance, but its origins stretch back much further than most riders imagine. Its story begins in 1879, when Thomas Edison carbonized thin bamboo fibres to create filaments for his light bulbs. While these early fibres bear little resemblance to today’s aerospace-grade composites, the fundamental concept—transforming organic material into pure carbon—was the spark that eventually led to one of the most transformative materials in cycling.

The real breakthrough arrived almost a century later. During the 1950s and 1960s, engineers in aerospace and defense were searching for materials that could withstand extreme stress while remaining incredibly light. Scientists in the United Kingdom refined polyacrylonitrile-based carbon fibre into the strong, consistent material we recognize today. The United States advanced the technology through military and space research, while Japan, especially Toray Industries, mastered scaling and precision. These developments were never intended for bicycles, but they laid the foundation for everything that would follow.

By the late 1970s, bicycle manufacturers began experimenting with carbon tubes bonded into aluminium lugs. These early frames were astonishingly light, but inconsistent manufacturing and adhesive failures made them unpredictable. Still, they proved that carbon’s potential in cycling was enormous.

Real progress arrived in the 1980s. In 1983, the Specialized Epic became the first mass-produced carbon frame, a major milestone in bicycle engineering. But the real revolution came in 1986 with the Kestrel 4000—the first true monocoque carbon frame. Instead of relying on tubes and joints, the entire structure was moulded as a single piece. It allowed engineers to sculpt aerodynamic shapes, fine-tune stiffness, and control flex in ways impossible with metal. Carbon fibre stopped being a novelty and started becoming the future.

As carbon fibre became more popular through the 1990s and 2000s, brands like Trek, Look, and Giant refined the material, improving consistency, strength, and ride feel. But one brand that has become synonymous with precision carbon engineering is Orbea. Their Orca line, first introduced as a full-carbon monocoque, represents decades of iterative improvement. Orbea’s use of different carbon grades, such as OMR and OMX, allows them to create frames that are stiff where riders need explosive power and compliant where comfort matters.

For riders looking for endurance or adventure, Orbea’s Terra line shows how carbon can also be versatile. Its gravel frames are light, efficient, and capable of handling long rides on mixed terrain without sacrificing ride quality. On the mountain bike side, Orbea’s Oiz full-suspension models illustrate carbon’s adaptability in the XC space, providing lightweight frames that remain stiff and responsive over rough trails.

Carbon Orbea Bikes

Orbea Orca M30i: Lightweight and race-ready road bike with Orbea’s OMR carbon frame — a great all-around performer for fast group rides or long solo days.

Orbea Orca M30i LTD: A higher-spec version of the Orca road bike, tuned for performance and stiffness, ideal for riders who want a refined carbon race machine.

Orbea Terra M20i Team: The 2025 Terra M20iTeam is a carbon gravel bike optimized for mixed terrain, with electronic Shimano GRX Di2 shifting.

Meanwhile, brands like Silverback demonstrate that carbon isn’t just for road bikes. Silverback’s CF SBC cross-country mountain bike frame, for example, uses a combination of 3K twill and unidirectional carbon to achieve a perfect balance of stiffness and compliance. It’s a platform built to excel on 29-inch wheels and demanding trails, showing how carbon fibre can be engineered for both racing and rugged durability.

Carbon Silverback Bikes

Silverback S‑Electro Pro CF 1: Dual-suspension carbon e‑enduro bike with 150 mm front and 145 mm rear travel, powered by a Shimano EP801 motor — built to climb and descend with electric assist.

Silverback Stratos CF SX: A carbon full‑suspension cross-country mountain bike — 3K twill carbon, modern geometry.

Silverback Siablo CF: Carbon gravel bike, balancing smooth road efficiency with the ability to handle rougher terrain — ideal for adventure, mixed-surface rides, and bikepacking.

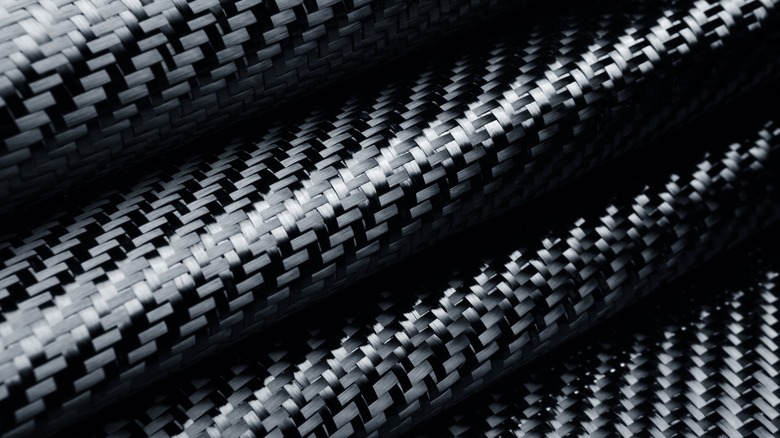

To understand why carbon performs so uniquely, it helps to look at how it’s created. Everything begins with polyacrylonitrile fibres, which are heated to extreme temperatures to remove non-carbon atoms and form long chains of crystalline carbon. These fibres are then woven into sheets and impregnated with epoxy resin, creating prepreg carbon. Skilled technicians cut hundreds of these pieces and place them inside moulds with incredible precision. Once heated and pressurised, the resin cures, forming a seamless, monocoque frame.

It’s this meticulous layering that allows brands like Orbea to tune stiffness, compliance, and ride characteristics. Silverback applies the same principle in mountain bikes, varying the fibre orientation to create frames that remain lightweight yet strong under aggressive XC riding.

Not all carbon fibres are the same. In cycling, Today’s T700, T800, and T1000 fibres are among the most widely used. T700 is resilient and comfortable, ideal for endurance or gravel frames like the Orbea Terra. T800 adds stiffness and weight savings for high-performance models such as the Orca M20i LTD. T1000, reserved for extreme racing applications, appears in targeted areas of top-tier frames to deliver maximum power transfer and responsiveness.

Carbon’s magic lies in layup design. Engineers orient fibres in different directions to balance vertical compliance, lateral stiffness, and torsional rigidity. The result is a ride that can be both lightweight and comfortable, stiff yet forgiving—a level of control that aluminium or titanium simply cannot match.

Carbon’s true strength is its tunability, enabling designers to craft bikes for climbing, racing, endurance, or XC competition, all from the same raw material.

Orbea and Silverback illustrate these principles beautifully. Orbea’s road and gravel frames focus on precision, efficiency, and performance, while Silverback’s mountain bikes show how carbon can absorb trail chatter and maintain responsiveness in demanding off-road conditions.

Carbon is often perceived as fragile, but it is highly repairable. Skilled technicians can restore damaged frames to full strength, layering new fibres and curing them carefully. Many repaired carbon frames end up as strong—or stronger—than before, giving riders confidence that their investment can endure beyond a single impact.

Even today, carbon continues to evolve. Robotic layups, thermoplastic resins, and graphene-infused materials are expanding possibilities, while one-piece monocoque frames push the limits of manufacturing and performance. Whether it’s the aerodynamic Orca, the versatile Terra, or Silverback’s trail-ready CF SBC, carbon continues to redefine what bicycles can do.

From light bulbs to aerospace to the most advanced bikes on the planet, carbon fibre has transformed cycling. And as brands like Orbea and Silverback continue to innovate, the future promises bikes that are lighter, stiffer, and more responsive than ever before.

You must be logged in to comment. Click here to log in.

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Please enter your ID number to validate your DStv Subscription.

No comments yet. Be the first to comment!